Master Plumbers October FAQ: Do you know the answer?

There’s been a lot of talk lately in the plumbing industry about restrictions on multi-layer piping and plastic-coated, semi-rigid stainless steel gas piping systems and for good reason. These restrictions are important for safety and compliance.

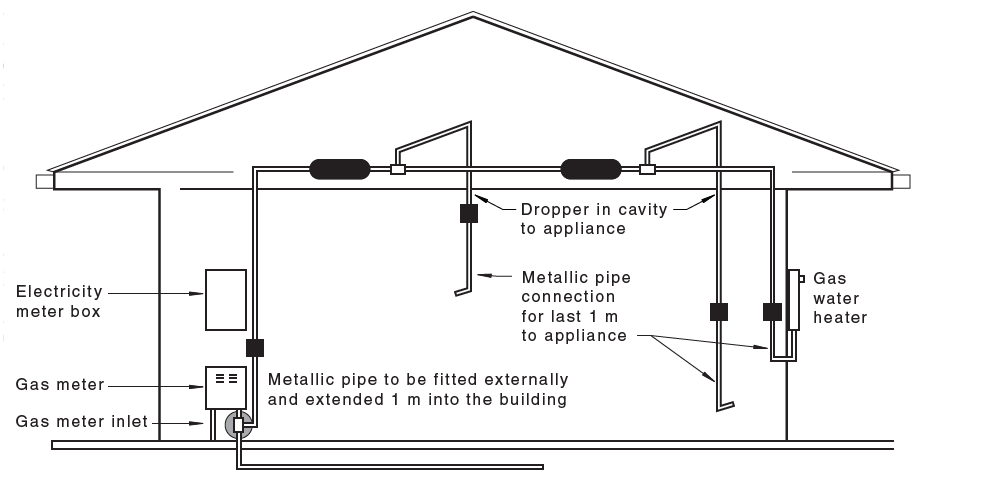

One key requirement is that these types of piping must terminate at least one metre away from any gas appliance. As outlined in AS 5601.1 Clause 6.6.1, this rule is in place to prevent heat damage from the appliance affecting the integrity of the piping system. In practice, this means you’ll need to transition to metallic pipework at least one metre from the appliance connection point.

Another key point is consumer piping external to the building shall be metallic and extend at least 1m into the building as per table 4.2 limiting conditions.

Another important safety note: brazing, welding, or annealing must not be carried out within one metre of any joint that contains non-metallic components, as specified in Clause 5.2.12. This helps avoid compromising the joint through heat exposure.

While we’re on the topic of joints, let’s touch on mechanical joint restrictions. Compression and flare fittings must be accessible; this ensures the nut can be properly tightened and maintained.

Screwed pipe fittings are only permitted in accessible and ventilated locations, as per Clause 5.1.7. Just to clarify, “accessible” is defined in the standard as: access can be gained without hazard or undue difficulty for inspection, repair, testing, renewal, or operational purposes.

Need immediate clarity? As a Master Plumbers member, you gain exclusive access to our in-house Technical Experts, who are available on-call for immediate advice and solutions to any technical challenge. Stop guessing and start solving. Discover the full value a Master Plumbers membership brings to you and your business below.