Now with 360˚ Detect

>B< Press 360˚ Detect makes unpressed fittings impossible to miss, giving lasting confidence every fitting is secure. Available in 15–50mm water fittings.

Expect nothing greater. Accept nothing less.

With more than a century of proven excellence, Conex Bänninger is the name plumbing and HVAC-R professionals trust in >B< Press fittings.

Conex-Bänninger

For more than 110 years, Conex Bänninger has been a recognised global leader in plumbing fittings, accessories, and valves—offering a trusted range of stainless steel and copper >B< Press systems.

Our range

15-50mm

>B< Press

>B< Press is a versatile press fitting system that provides a secure, permanent and leak-proof joint suitable for a variety of applications.

65-100mm

>B< Press XL

>B< Press XL is a functional press fitting system that provides a secure, permanent and leak-proof joint suitable for commercial applications.

1/4" - 1 3/8"

>B< MaxiPro

>B< MaxiPro is an innovative press fitting that provides a secure, permanent and leak-proof joint suitable for both refrigeration and air conditioning applications.

15-54mm

>B< Press Stainless Steel

>B< Press Stainless Steel is a versatile press fitting system that provides a secure, permanent and leak-proof joint suitable for industrial applications.

Why choose Conex Bänninger?

Conex Bänninger has partnered with Rothenberger and Reece to design >B< Press and >B< MaxiPro for Australian conditions. With rigorous testing, unmatched availability and expert support, you can feel confident that >B< Press has got you covered.

>B< Press 360˚ Detect

Engineered with a smarter leak-path design and a tougher material, 360˚ Detect makes it far easier to spot any unpressed fitting during testing. It creates a clear, intentional leak point at a higher flow rate, so unpressed joints stand out instantly.

Press tool calibration

Exposure to dirt, mud and water along with constant use can cause your press tools to lose performance slowly. We know how important yours is to your business, so next time you’re in branch, drop your Rothenberger press tool at our your local Reece branch for a free calibration and service. We’ll ensure it’s working its best, so you can too.

Certification training

Learn how to avoid common errors and gain technical advice and expertise with Conex Bänninger’s free install training for >B< Press and >B< MaxiPro.

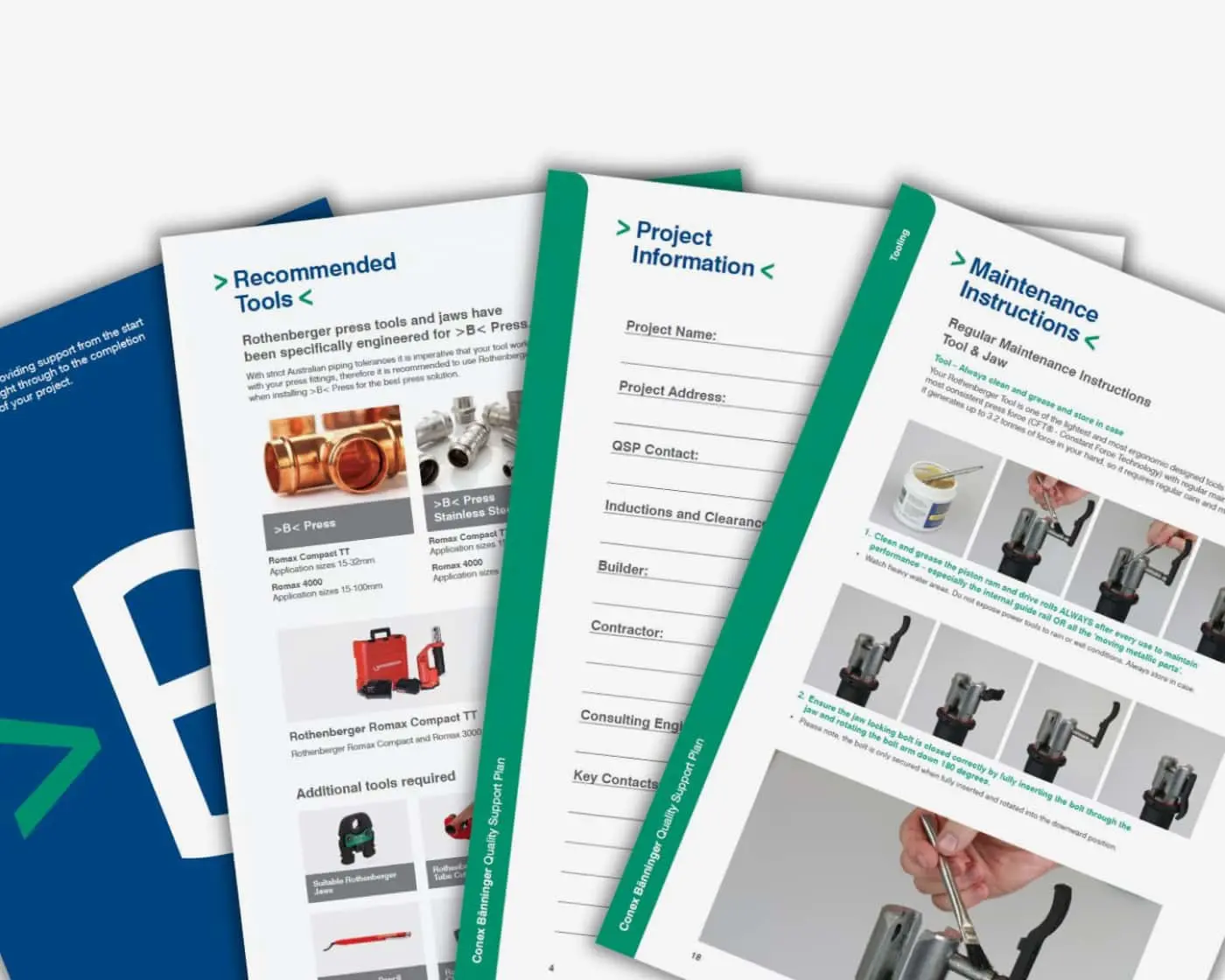

Project resources

From testing logs to installation guides, contact Conex Bänninger to get your personalised Quality Support Plan for handy resources to help your next project run smoothly.

>B< Press 360° Detect makes unpressed fittings unmissable

The total >B< Press solution

Designed for Australia

Developed in partnership with Reece and Rothenberger to meet the specific needs of the Australian market.

Extensive testing

All Conex Bänninger fittings undergo rigorous internal testing to ensure they meet Australian standards and piping tolerances.

Training & certification

We’re here to help you succeed with training and certification, as well as technical guidance and advice whenever you need it.

Tool service support

Get your Rothenberger press tools serviced for free through the Reece Tool Servicing Department. Available at your local plumbing branch.

Visit your local branch

With hundreds of locations across Australia, there’s sure to be one near you.