Tool Servicing Department

Keep your press tools in top condition and performing as they should. Simply drop them off at your nearest branch and we’ll take care of the rest.

Annual service press checks

Exposure to dirt, mud and water along with constant use can cause your tool to lose performance slowly, making an annual service press check vital. We assess each unit individually and put it through a rigorous service procedure to ensure your Rothenberger tools continue to work at its best, so you can too.

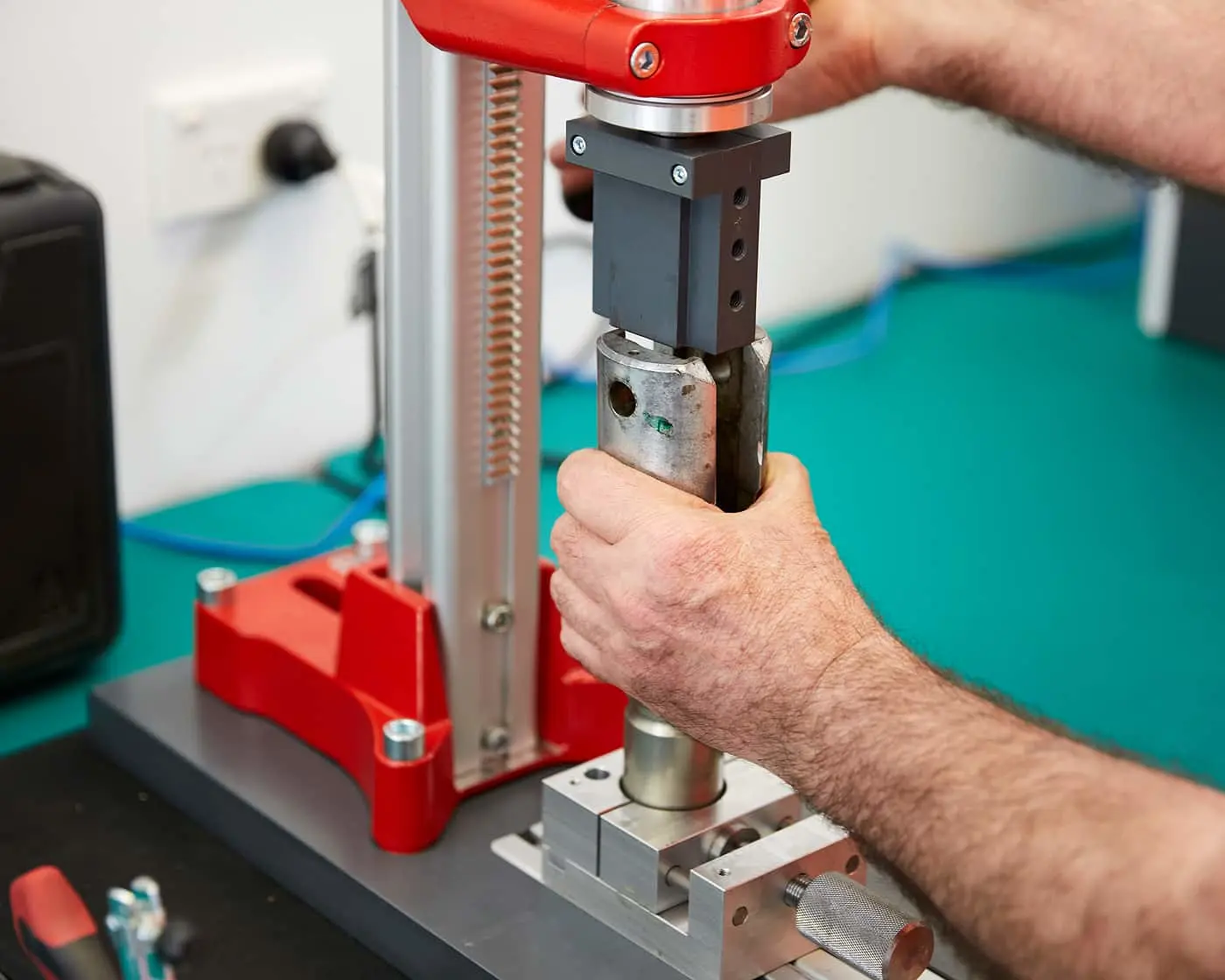

Visual functioning test

We meticulously check and test parts that can cause major issues until they’re working like new. These include the locking pin, jaw holder, head roller and printed circuit board. Only genuine Rothenberger parts are used.

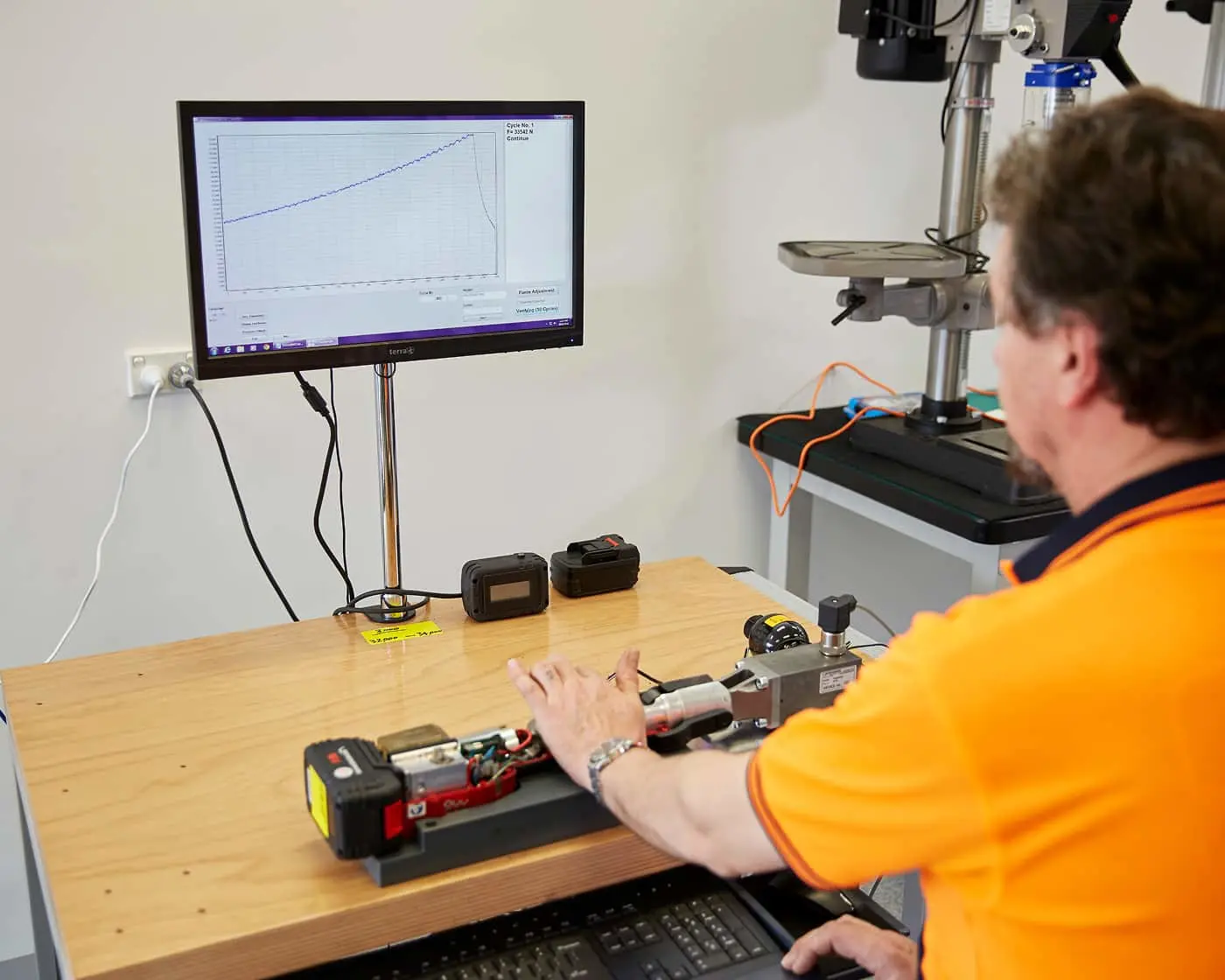

Calibration test

When we’re satisfied with the condition of your tool, we conduct a force reading test to show your tool’s crimping strength. We make ten simultaneous crimps to ensure your tool falls within the appropriate force range.

External clean

All tools receive a detailed clean before re-assembly. We pride ourselves on delivering the highest standards and want your tool to look and feel almost brand new after its service.

Detailed service reports

When your tool is returned, you’ll receive supporting documentation outlining all the work performed, including a Calibration Test Report, a Service/Repair Job Report, and a Service Reminder to help you stay on top of future maintenance.

Visit your local branch

With hundreds of locations across Australia, there’s sure to be one near you.